ProBlock set out to create a masonry product that would change the building industry. Our architect partners were top of mind when we designed our products.

ProBlock Insulated Wall System offers architects an innovative masonry unit that helps deliver a beautiful project within schedule, under budget, and at the highest level of building performance possible. ProBlock helps you meet these goals and more.

Energy Efficient – High R-value masonry

Lower Project Cost – Against other wall systems

Improved Timelines – Shortened masonry schedule

Benefits Include:

Energy Code Compliance – Enables single-wythe masonry to more easily comply with energy code

Energy Efficiency – Achieve R-values up to 19

Competitive Cost Structure – Other high R-value masonry systems can be cost prohibitive; ProBlock offers the economic savings of single-wythe masonry construction

Compliance – ProBlock complies with ASTM C90

Shortened Construction Schedule – Lightening the load of the mason increases productivity

Reduced Construction Cost – Higher productivity per mason means lower cost for you

Design Flexibility – Open up the realm of architectural design possibility

Innovative Design – Engineered to maximize masonry performance

The ProBlock Insulated Wall System

Whole-wall R-values for ProBlock walls are much greater than conventional 3-web concrete block walls. The increase achieved by injecting aminoplast foam insulation is up to 264% greater than is possible with normal weight concrete masonry walls injected with the same aminoplast foam insulation.

ProBlock provides significant reduction in thermal bridging

ProBlock Provides Optimal Thermal Performance

R-value is the measure of thermal resistance used in the construction industry. Higher R-value equates to increased resistance to heat flow. R-value measures the ratio of the temperature difference across an insulator (concrete masonry wall) and the heat flux (heat transfer per unit area per unit time).

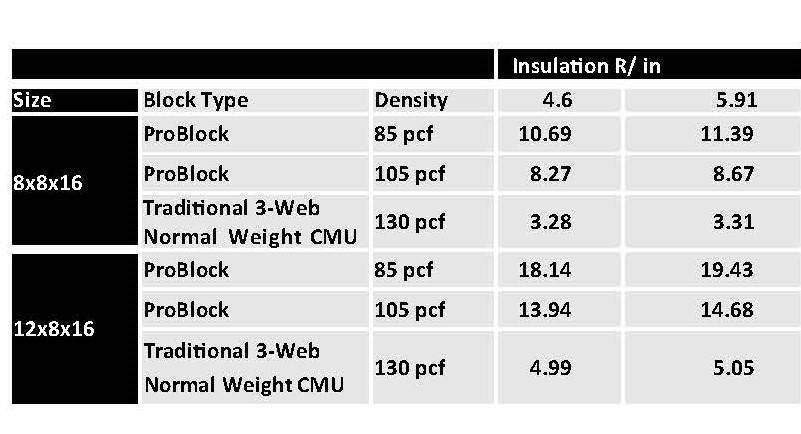

The key to maximizing whole-wall R-values of concrete masonry walls is minimizing thermal bridges within the concrete masonry units and increasing the thermal resistance of the concrete used to produce concrete masonry units. Lightweight concrete is ideal for highest thermal performance concrete masonry wall assemblies. The table below illustrates the exceptional thermal performances that can be achieved by specifying ProBlock Masonry Wall System filled with aminoplast foam insulation.

R-Values for Concrete Masonry Walls (Exposed Both Sides)

Energy Performance Within a Wall System

R-values of ProBlock walls insulated with aminoplast foam compare favorably to those insulated with closed-cell polyurethane foam. Because aminoplast foam flows within the wall, all of the nooks & crannies get filled.

Polyurethane foam expands rather than flows; thus, many more holes must be drilled & patched, expanding foam tends to bridge small openings to leave voids, and polyurethane foam typically costs far more than aminoplast foam insulation.

For these reasons – better performance and faster installation at a lower cost – aminoplast foam insulation @ R-4.60/inch is the better choice for injecting ProBlock walls vs. closed-cell polyurethane foam insulation @ R-5.91/inch. The table below illustrates how closely whole-wall R-values track one another no matter the type of foam used to fill core-cells of ProBlock walls.

R-Values Foam Insulated Walls

Insulated by injecting R-4.6/inch core foam masonry insulation

Energy Code Compliance Using COMCheck Demonstration Analysis

When using COMCheck for energy code compliance demonstration analysis, the U-value for the wall assembly should be used in the “other mass wall” section of the program. In COMCheck, when the "other mass" section is used, the heat capacity (HC) of the wall assembly must be used in conjunction with the U-value.